Magneetsystemen

Voordelige magneetsystemen voor veel toepassingen

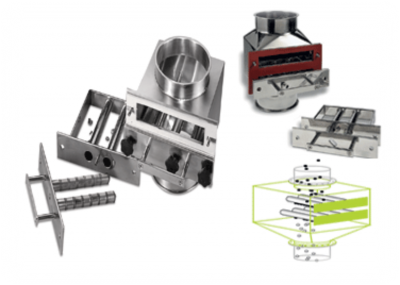

Het uitgebreide programma van magneten en magneetsystemen is een aanvulling op de metaaldetectie systemen en x-ray apparatuur. Met deze magneten worden magnetische metalen uit de productstroom gefilterd. Doordat er gebruik gemaakt wordt van Neodymium hebben de magneten een geweldige kracht dat zelfs zwak magnetisch RVS kan aantrekken!

Er zijn magneetsystemen leverbaar voor de voedingsmiddelen-, chemische- en farmaceutische industrie. De uitvoering is afhankelijk van het te filteren product. Zo zijn er vrije val magneetsystemen voor producten in vaste vorm zoals poeders, granulaten, korrels en vlokken. Zelfs voor een drukleiding (pneumatisch transport) is er een speciaal magneetsysteem. Voor vloeistoffen is er de LiquiMag die eventueel dubbelwandig uitgevoerd kan worden voor bijvoorbeeld makkelijk stollende chocolade producten. Voor stortgoederen op een lopende band zijn er rolmagneten beschikbaar die de eindrol vervangen. Het metaal kan dan met een simpele trechter uit het goede product gesepareerd worden.

De niet-magnetische hulzen die over de magneetstaven zitten maken het reinigen erg makkelijk en snel. Zeker gezien de enorme sterkte van de magneten maakt dit het reinigen eenvoudig. Men haalt de magneetstaaf samen met de huls uit het systeem. Daarna kan de magneetstaaf uit de huls gehaald worden, de ijzerdeeltjes komen dan direct los van de huls.

Magbox Auto Clean

De Magbox Auto Clean wordt bij continue draaiende productielijnen ingezet. Het vernuftige ontwerp separeert de ijzer deeltjes. Er zijn twee uitlaten, één voor de verontreiniging en één voor het schone product. Ondanks het ingenieuze ontwerp is de inbouwhoogte slechts 400 mm. De interval voor de automatische reiniging is instelbaar

Uitermate geschikt voor de voedingsindustrie

Het grote en intuïtieve touchscreen maakt het instellen zeer eenvoudig. Verder is onze jarenlange ervaring in de levensmiddelenindustrie ook terug te vinden in het ontwerp van de transportband systemen die eenvoudig te reinigen zijn. Deze serie kan geleverd worden in een volledig roestvast stalen uitvoering of met een stalen frame.

LiquiMag

Voor alle verpompbare vloeibare producten is er de LiquiMag. De LiquiMag kan eenvoudig in een bestaande leiding ingebouwd worden. Het product stroomt langs de krachtige magneetstaven waardoor alle magnetische verontreinigingen gescheiden worden van het product. Bij verwarmde leidingen voor makkelijk stollende vloeistoffen kan de LiquiMag dubbelwandig uitgevoerd worden voor verwarming van de behuizing. Deze magneetsystemen voldoen aan de strengste hygiëne eisen waardoor ze geschikt zijn voor zowel de voedings-, chemische- als farmaceutische industrie.

Extruder magneten

Deze serie is speciaal ontworpen voor spuitgiet machines in de plastic industrie. Deze magneet wordt in de toevoer van het granulaat ingebouwd en zorgt ervoor dat er geen ijzer deeltjes in de extruder komen ter voorkoming van schade aan de schroef en spuitnippel. Zelfs bij een temperatuur van 80 graden Celsius doet deze magneet zijn werk.

Nog meer uitvoeringen

Er zijn vele uitvoeringen verkrijgbaar voor de meest uiteenlopende producten. Wij informeren u graag over de beste oplossing voor uw product. Een beknopte overzichtsbrochure kan eenvoudig aangevraagd worden via het informatie formulier hier.

BEZOEK ONS

Minervum 7404, 4817 ZG Breda

BEL ONS

(+31)76-581 55 99

EMAIL onS

info@stolsystems.com